In this blog we talk about how to control hazardous chemicals in your workplace.

Check the video out as Michael Terry of Momentum Safety discusses what you need to know about hazardous chemicals in your office, your factory, your workshop or anywhere in your workplace.

Video Transcription

1. Identification

To start, you need to identify all the hazardous chemicals in your workplace.

As per all your different hazard topics, one of the main things that you need to do is consult with your workers before you go too far. They know what’s going on, they know the chemicals they use and they’ll be able to give you some really good information.

To help, you should be looking at the chemical label. That has some really good clear information about what some of the hazards might be.

However, the main source of information for hazardous chemicals is the Safety Data Sheet.

The Safety Data Sheet is the information manual or instruction manual on that particular chemical. It has the information that you might need to know what the different hazards might be.

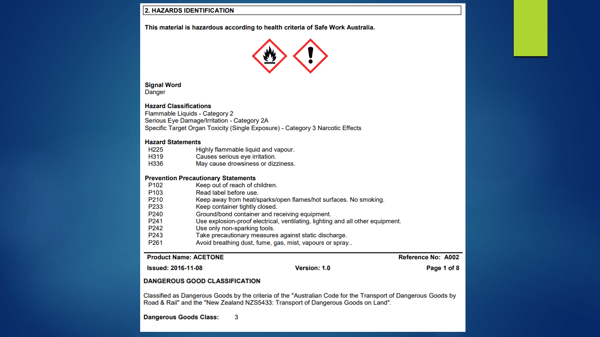

When you review the Safety Data Sheet, you need to look at a few key points. Firstly you need to look whether the chemical is actually hazardous or not. This will be clearly shown in the Safety Data Sheet.

In this image you can see an example of a safety data sheet. This is where you can see whether the chemical is actually hazardous or not.

If it is not hazardous, you don’t need to worry. Move onto the next chemical.

If it is hazardous, from here on in this information is going to be really important.

2. Assessment

The next thing you need to do is a risk assessment on that chemical.

There are really 3 different types of risk assessments you can do.

First up you can do a very basic risk assessment.

This can be contained on the register of chemicals that you have done in step 1 "Identification" above.

Here is an example of a really basic risk assessment. This lists the chemicals and gives them a score or rating on the risk level of that chemical.

The next type of risk assessment is a generic risk assessment.

In this you can bundle chemicals, of different types, into one category and risk assess them altogether. This is a really handy way of getting a lot of risk assessments done on a bunch of different chemicals. For example, paints, will all have the same types of risk levels.

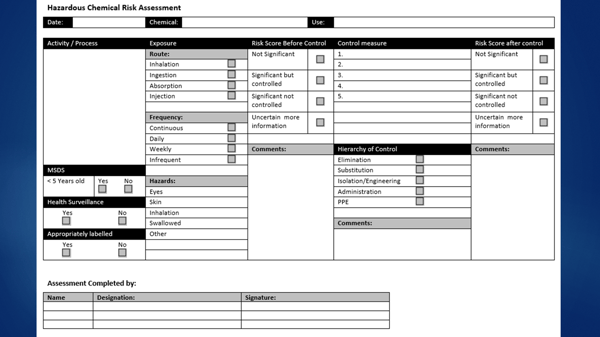

The final one that we need to do is a detailed risk assessment.

Above is an example of a detailed risk assessment form that you might do for some of those more tricky chemicals.

3. Risk Control

Next you need to think about risk control.

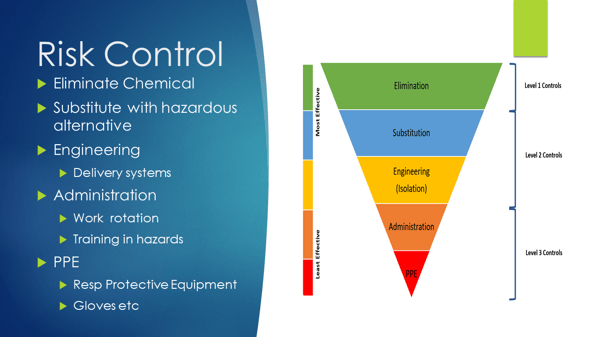

When you’re controlling risk, you can use the Hierarchy of Control.

The Hierarchy of Control describes your first option you should try is to eliminate the chemical. However, most of the time you can’t eliminate the use of the chemical.

Therefore you need to look for better options.

For example there might be a safer option for a cleaning chemical. You might be using a cleaning chemical that is quite hazardous and you can look for another cleaning chemical, which does the same job, but is less hazardous, then that’s substitution.

Engineering controls is our third option.

This is where you can use some sort of physical change to the actual workplace. So it might be something like a delivery system (see above), where the chemical is contained and it’s delivered in an enclosed system.

Some of our administrative controls will be things like task rotation. This is where you make sure that the same worker is not always using the hazardous chemical all the time. You share that exposure out between multiple workers or simply training in the use of the chemical.

And the final control is using personal protective equipment (PPE).

This is where you use respiratory equipment, gloves, masks and goggles (see image above).

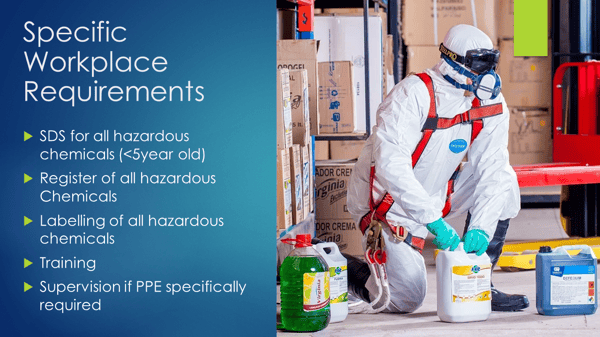

Summary of Specific Workplace Requirements

There is some specific workplace requirements that are part of the Health and Safety regulations.

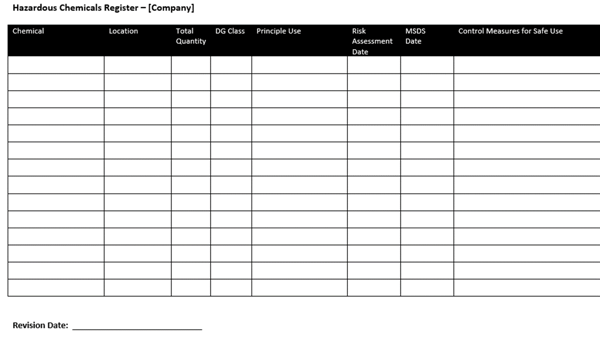

Register

You need a chemical register for all the hazardous chemicals that you have in the workplace.

The register will include: -

- List of hazardous chemicals

- Where they’re located

- Risk assessments for the chemical

- Control measures for that chemical

Safety Data Sheet

You need to make sure that you have Safety Data Sheets for every chemical. These must be less than 5 years old according to the health and safety regulations.

Labelling

You need to make sure that every hazardous chemical in the workplace is labelled. There must be an appropriate label on the container to ensure that you’re not getting different chemicals confused.

Training

You need to make sure that you train your workers, where appropriate.

Personal Protective Equipment

You need to make sure that you use personal protective equipment, where appropriate.

Placards, Signage and Manifest

There is also another couple of particular requirements when your hazardous chemicals exceed certain volumes. This includes placarding. So this is a specific signage requirement and manifest requirements as well. Therefore you need a certain type of manifest for high volume hazardous chemicals

Takeaways

- You MUST have those safety data sheets for all our hazardous chemicals

- Those safety data sheets must be contained on a hazardous chemicals register.

- You just need to make sure that you have appropriate controls in place, which are always going to be implemented using the Hierarchy of Controls.

- If you are using controls such as training and personal protective equipment, they need to be really clearly documented and you need to have systems in place to make sure that they’re actually happening.

.png?width=200&height=51&name=image%20(2).png)